Insulating Glass

You are interested or you are having questions?

Insulating Glass Unit

Insulating glass consists of assembling two or more individual lites separated by a dehydrated and hermetically sealed air space. These sealed units contribute to improved building energy performance.

By changing the number, type and thickness of the components used, we can create a wide range of glazings that meet specific requirements such as:

- Countering solar heat gain

- Preventing heat loss in winter

- Resisting wind and snow loads

- Improving natural light quality, while enhancing the appearance of a building

CHARACTERISTICS

- Measures the standard thickness of insulated glass units for ICI (industrial, commercial and institutional) buildings—25 mm—with two lites of 6 mm glass and an air space of 13 mm. Other configurations are available to meet certain specific requirements.

- Available in large formats

Standards and Certifications

CAN/CGSB 12.8 – Insulating Glass,

ASTM E 2190 – Insulating glass unit performance and evaluation,

GANA Glazing Manual – Glass Association of North America,

IGMA – Insulating Glass Manufacturers Alliance

Component options

Glass

- Substrates: clear, ultraclear, tinted (grey, bronze, green, blue, etc.)

- Low-e: LoE² 272, LoE³ 366, LoE² 240, etc.

- Reflective: Eclipse Advantage™, Solarcool®, etc.

- Laminated: clear, tinted, translucent, decorative: Vanceva®, etc.

- Printed: Silkscreened Prel-Design, In-Glass Printed Prel-Design

- Low maintenance: Neat®

Spacers

R-Max™, LPS Stainless Steel, LPX aluminum

Filling Gas

Argon or air

Seal

Grey or black silicone, polyisobutylene (PIB)

Try our ThermaSpec online tool to compare the optical and thermal performances of our complete line of insulating glass units.

Applications

Vertical glazing

Punch windows, curtain walls, spider systems

Sloped glazing

Skylights, canopies, roof windows

Documentation

Prel-UniT Brochure – Insulating Glass Units

Consult the tools section for all our documentation.

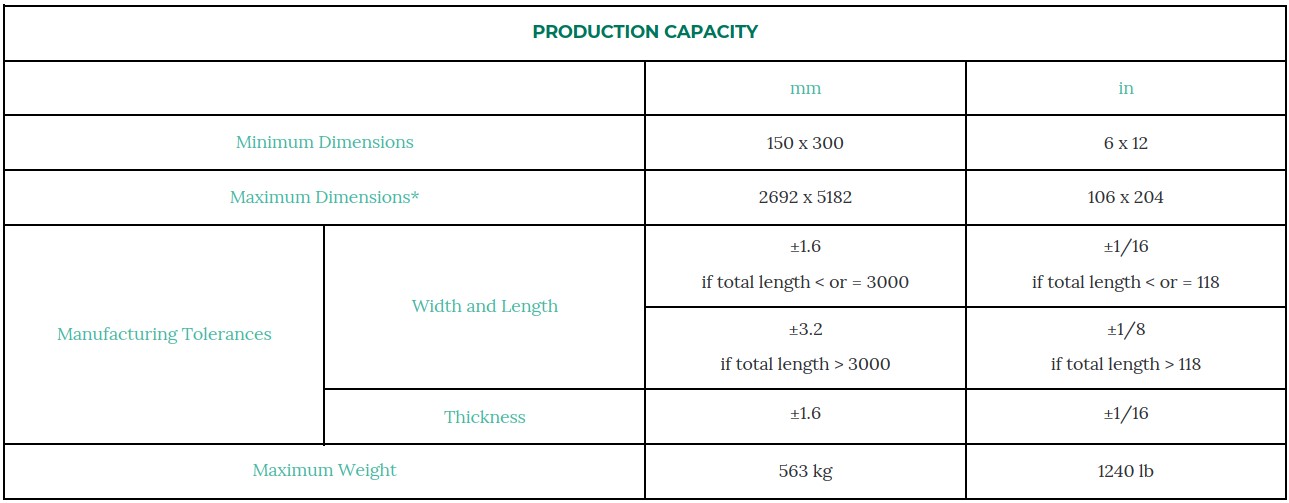

PRODUCTION CAPACITY

* Maximum insulated glass unit dimensions are determined by a number of factors, such as their thickness, weight, ratio of width/height, application and loads (ex. wind and snow). Maximum, achievable, dimensions do not imply that sealed units manufactured to these dimensions will meet all laws, rules, regulations and other requirements. It is up to the user to ensure that the products they order are suitable for their intended use.